Tableware Plant Kitchenware Fork Spoon Steel Plate Rolling Mill Machine for Cutlery Manufacturing

Basic Info.

| Model NO. | complete production line |

| Movement Mode | Linear |

| Usage | Metal Production Making |

| Appearance | Open-Type |

| Max Feeding (mm) | 500 |

| Motor Power(kw) | 1~10 |

| Installation Slope | 0 |

| Chute size(mm) | 4900×1100 |

| Overall Dimension | 3920×1640×1320 |

| Dimension(L*W*H) | Length: 8-12m |

| Stock Thickness | 0.3-3.2mm |

| Applicable Industries | Manufacturing Plant, Home Use |

| Max Line Speed | 24m/Min |

| Machinery Test Report | Provided |

| Service | 1by1 Video Serivce |

| Video Outgoing-Inspection | Provided |

| Transport Package | Sea Shipping |

| Specification | 13800*2500*2200mm |

| Trademark | SunGlory |

| Origin | China |

| Production Capacity | 20 Set/Sets Per Month |

Packaging & Delivery

Package Size 1440.00cm * 1000.00cm * 1200.00cm Package Gross Weight 5000.000kgProduct Description

Standard Configuration

1. Photoelectric are control system; 2. Height electric adjustment device; 3. Arc control roller; 4.Oil pressure expansion equipment of material rack; 5. Frequency control of material rack; 6. Press arm device; 7. The material rack includes air pressure disc brake device; 8. Oil pressure automatic loading trolley.

Parameters

---------------

| Item | HGS2-400 |

| Stock width | 75-400mm |

| Stock thickness | 0.3-3.2mm |

| Max coil weight | 3000kg |

| Max coil outer diameter | 1200mm |

| Max coil inner diameter | 508mm |

| Feed length | 9999.9mm |

| Max. line speed | 24m/min |

| Work roll number | upper5/ lower4 |

| Feed roll number | 1 set |

| Main motor | AC1.8kw |

| Reel motor | 1.5kw |

| Mandrel expansion | Hydraulic |

| Power supply | 3 phase 220V/380V/50Hz |

| Operating Air | 0.5Mpa |

Advantages

1. Easy maintenance: Semi-auto lubricate system2. Easy operation: Unskilled ladies or freshman can operate the machine 3. Double-start-button safe-protection system

4. Feedback by clients that machine frame life over 10 years

5. Custom service is available

Rectifying Capabilities

---------------

| Model | HGS2-400 | HGS2-600 | HGS2-800 | HGS2-1000 | HGS2-1300 | |

| Stock thickness | 1.3MM | 400 | 600 | 800 | 1000 | 1300 |

| 1.6MM | 400 | 600 | 700 | 900 | 1000 | |

| 2.0MM | 400 | 600 | 470 | 750 | 700 | |

| 2.3MM | 400 | 440 | 350 | 600 | 600 | |

| 2.5MM | 400 | 380 | 300 | 450 | 450 | |

| 3.2MM | 250 | 230 | 230 | 230 | 230 | |

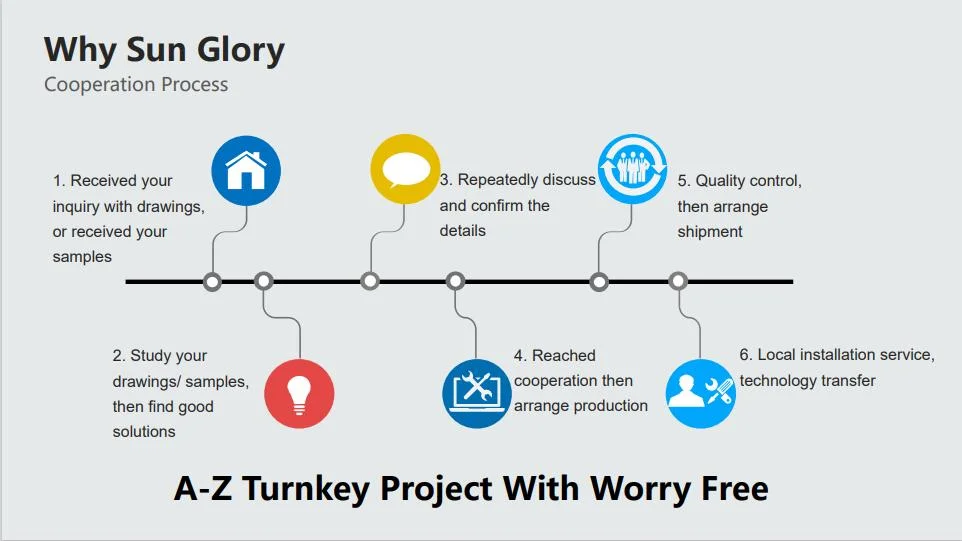

Services

-----------

Pre-sale Service

1. Popular design, new trend information sharing.

2. Return of investment analysis.

3. A-Z solution flow chat design.

4. Production process design and feasibility study.

5. Machines line arrangement.

In-sale Service

1. Machines and molds quality control during manufacturing and after finish.

2. Independent verification for each process.

After-sale Service

1. Plant layout proof & production line positioning.

2. Production line installation & debugging.

3. Training after shipment in buyer's factory.

4. Annual visit on site.

Upgraded Service

1. Market trend & latest fashion broad casting.

2. Continuous & systematic training for management, maintenance team & operators.

3. Back up for the regular production.

4. Support in new R&D realization.