Surface Machine Automatic Gooda End Grinding Gantry Machining Center Hg

Let GOODA help you keeping quality at 100%! Dongguan GooDa Machinery Manufacturing Co.,Ltd established in 2012, is the f

Basic Info.

| Model NO. | HG-1825NC |

| Automatic Grade | Automatic |

| Cylindrical Grinder Type | End Cylindrical Grinder |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Max Length | 2500 |

| Controller System | Optional,Siemens/Fanuc/Mitsubishi |

| Mini Feed Size | 0.005 |

| Max Width | 1600 |

| Max Height | 600mm |

| Max Loading Weight | 6000kg |

| Column Width | 1800mm |

| Transport Package | Wooden or Steel Box |

| Specification | 5.7*3.9m |

| Trademark | GooDa |

| Origin | China |

| HS Code | 8459619000 |

| Production Capacity | 500sets/Year |

Product Description

Let GOODA help you keeping quality at 100%!

Dongguan GooDa Machinery Manufacturing Co.,Ltd established in 2012, is the first national high-tech enterprise integrating R&D,manufacturing,sales and service of CNC milling machine tools in China.The company has manufacturing bases in Dongguan Changping,Huangjiang,Qishi and Jiangsu Kunshan, and offices in the United States,South Korea, Malaysia,Thailand,Vietnam and Brazil.At present, it is one of the largest manufacturer of CNC Duplex milling machines in the world.GooDa Machinery focuses on the field of CNC duplex milling machine, and has maintained rapid development since its establishment. Its independent brands: GooDa machinery,YaGoo machinery and JJR machinery have become the most influential brands in the industry. The design and positioning of the product is guided by the customer's needs of users in different scales and fields, and realize personalized customization, so as to create the highest economic benefits for customers.

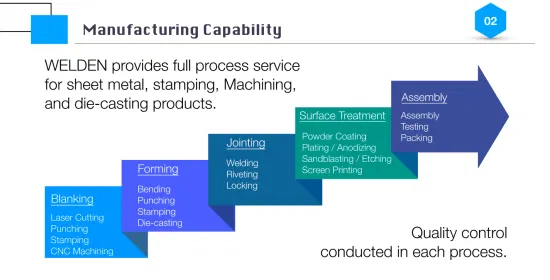

GOODA PLANAR GRINDING MACHINEMODLE : HG-1825NC

The horizontal grinding head adopts high-precision flange type spindle design. With three pairs of super-precision angular contact bearings (made in Japan/Germany), using high-temperature resistant high-grade lubricating grease, completely sealed, no need for additional maintenance. Therefore, it can maintain high quality characteristics such as low noise, high precision and low temperature during grinding.

The grinding machine is equipped with a safety type grinding wheel with buffer protection device. The wheel adopts reasonable structural transformation, so that the safety of the operator is guaranteed.

The worktable adopts the fully supported double V self-positioning type hard rail design, the base rail is processed by high frequency, HRC55°±3°, the worktable rail is affixed with PTFE rail tape, to ensure the good smoothness and guidance of the table motion rail.

Specification

| Item: CNC Planer Grinding Machine | Unit | Model | |

| HG-1825NC | |||

| Travel | Control Axis | No. | 4 |

| Maximum length | mm | 2500 | |

| Maximum width | mm | 1600 | |

| Maximum height | mm | 600 | |

| Column width | mm | 1800 | |

| Worktable | Table size | mm | 2500*1500 |

| Grinding Head | X feed speed | mm/min | 5-2800 |

| Y feed speed | mm/min | 5-3000 | |

| Z feed speed | mm/min | 5-3000 | |

| Z mini feed size | mm | 0.005 | |

| Power | kw | 18.5 | |

| Speed | rmp | 1400 | |

| Wheel | mm | 500*75*203 | |

| Motor | Hydraulic motor | Kw | 22 |

| Y motor | Kw | 2 | |

| Z motor | Kw | 2 | |

| Others | Max loading weight | kg | 6000 |

| Machine weight | kg | 29000 | |

| CNC system | - | FANUC SYSTEM OR Mitsubishi controller OR Siemens System | |

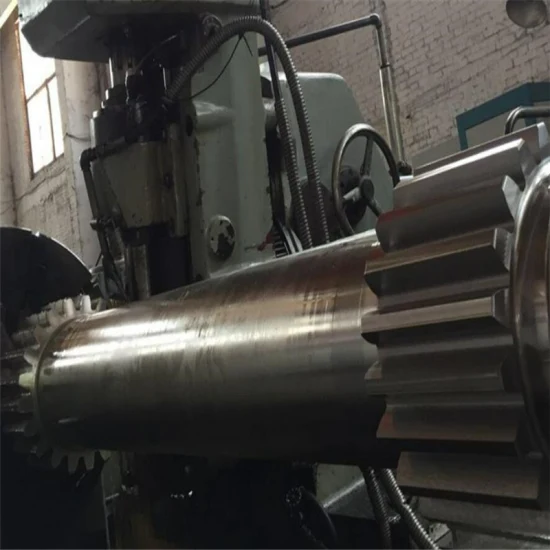

{Workshop}

Main products:CNC duplex milling machine,CNC high speed sawing machine, CNC Vertical milling machine,CNC Gantry milling machine, CNC Machining Center, CNC three Axis Chamfering machine,CNC Planar Grinding machine,Plate flipping machine.The application scope of the products includes mold steel,moldbase, aluminum plate,die processing and other metal cutting.After years of research and development and innovation, the products are at the leading level in terms of processing accuracy,machine stabilitym,Ergonomic design and other technical performance. With the continuous improvement of market demand, GooDa has launched six side processing solutions, indirectly promoting the development of China's mold industry.After years of unremitting efforts, the company has obtained dozens of patent technology and software coyright, and has successively passed the ISO 9001 quality management system certification of EU TUV certification body,EU CE product safety certification, intellectual property management system certification,national high-tech enterpise evaluation and other honors.In order to maintain the leading edge of product technology,the company has actively carried out school enterprise cooperation to continuously promote the development of the enterprise while recruiting excellent talents in the industry.Benefiting from the company's innovation and R&D advantages,the company has developed rapidly in just a few years. The existing R&D and production sites have restricted the company's subsequent development, and the space for capacity improvement is limited. For the company's sustainable development in the future, in 2018, GooDa invested heavily in the construction of GooDa machinery's normal headquarters Indusrial Park to support the development of the company's high-end CNC machine tool equipment project, Greatly enhance the company's CNC inteligent equipment capacit.

{CERTIFICATE}Manufacturer of CNC duplex milling machines and other series of professional CNC machine tools !!

{EXHIBITION }

Every feature,function and configuration of our machinery are made for our customer

Send to us