Steel Sheet Plate Metal Electric Bending Press Brake

Package Size 370.00cm * 175.00cm * 245.00cm Package Gross Weight 7500.000kg Products Description Details ImagesKCN Serie

Basic Info.

| Model NO. | KCN-10032 |

| Condition | New |

| Certification | ISO 9001:2008, CE |

| Automation | Automatic |

| Suitable for | Carbon Steel, Stainless Steel |

| Type | Hydraulic Bending Machine |

| Certificate | Ce |

| OEM | Ok |

| Brand | King Ball |

| Type for Pipe and Tube Bending Machine | Press Brake |

| Material | Steel Metal |

| Working Table | 3200mm |

| Garantee Time | 2 Years |

| Machine Type | CNC Press Brake |

| Color | All Color Are Available |

| Transport Package | Nude Package or Plastic Paper |

| Specification | CE&ISO standard |

| Trademark | KingBall |

| Origin | Jiangsu, China |

| HS Code | 8462230000 |

| Production Capacity | 100 Sets/Month |

Packaging & Delivery

Package Size 370.00cm * 175.00cm * 245.00cm Package Gross Weight 7500.000kgProduct Description

Products Description

| Electro-hydraulic CNC Press Brake | KCN-10025 | KCN-10032 | KCN-10040 | |||

| Capacity | kN | 1000 | 1000 | 1000 | ||

| Max. Bending Length | mm | 2500 | 3200 | 4000 | ||

| Between Columns | mm | 2100 | 2600 | 3100 | ||

| Max. Shut Height | mm | 480 | 480 | 480 | ||

| Slide Stroke | mm | 200 | 200 | 200 | ||

| Throat Depth | mm | 400 | 400 | 400 | ||

| Down Speed | mm/min | 160 | 160 | 160 | ||

| Pressing Speed | mm/min | 10 | 10 | 10 | ||

| Return Speed | mm/min | 130 | 130 | 130 | ||

| Main Motor Power | kW | 7.5 | 7.5 | 7.5 | ||

| X axis stroke | mm | 500 | 500 | 500 | ||

| X axis speed | mm/s | 300 | 300 | 300 | ||

| R axis stroke | mm | 200 | 200 | 200 | ||

| R axis speed | mm/s | 60 | 60 | 60 | ||

| Outline Size | L | mm | 3000 | 3700 | 4500 | |

| W | mm | 1750 | 1750 | 1750 | ||

| H | mm | 2450 | 2450 | 2450 | ||

| Weight | kg | 7000 | 7500 | 8000 | ||

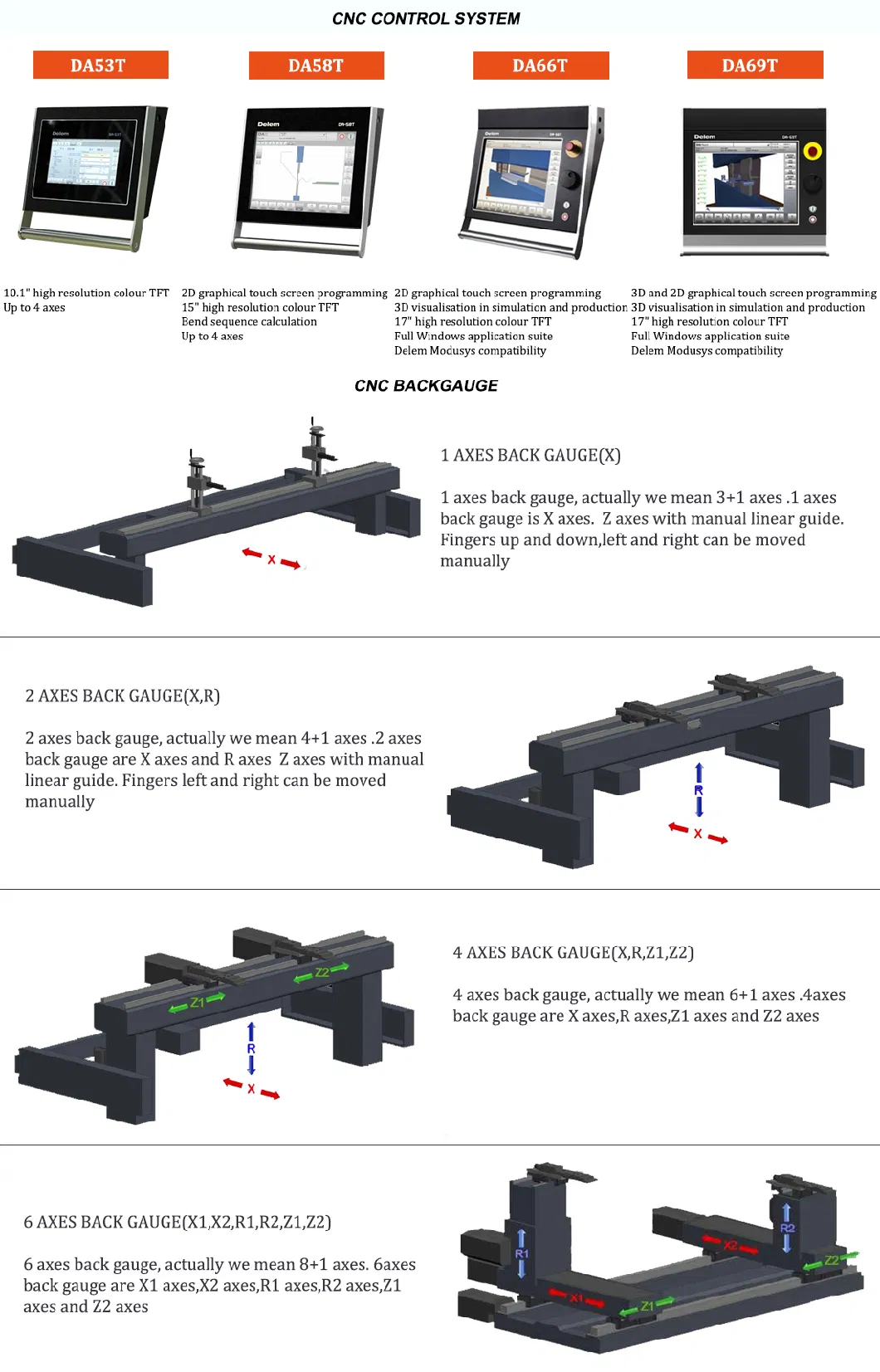

Details ImagesKCN Series Electro-hydraulic Synchronous CNC Press BrakeMain functions and featuresOverall welded and processed structure.Save electricity, Compared with the traditional transmission device, the electricity consumption is 50%.Within one stroke, bending pressure can be controlled at random point, repeatability precision±0.01, parallelism 0.02,high working effective, can improve 30%.The noise is reduced and the machine is quieter.Save oil, Hydraulic fluid use is very small, only for the traditional 50 %Lower worktable has crowning device to anti deflection & upper tool has wedge compensation device.Delem CNC control system, grating ruler, Rexroth hydraulics, servo motors and other accessories of famous brand are installed for perfect machine performance. Ram stroke(Y1, Y2),backgauge (X,R,Z) are controlled by CNC controller while ball screw and linear guide rail installed for high repeatability precision. Imported ball screw and linear guide are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

Main motor Delta servo motor SVP control technology,energy saving rate over 50%, avoid hydraulic oil fast heatingup,reduce hydraulic errors.Laser safety protectionDSP Laser safety device protects the press brake operator from the danger of crushing between the moving and fixed part of themachine.DSP Laser safety device is mounted on the moving part of the machine, and the protection zone moves with the part. When anobstacle is detected, such as an operators fingers, detection is immediate and the machine can be stopped.Bending followerSheet supporting plate can follow the workpiece during the bending. The following degree and speed are controlled by CNCcontroller. Bending-help device can move along linear guide left and rightThe height can be adjusted up and down manually, also the de-vice can move front and rear to match the die opening manually.Two choices for supporting table: Brush and stainless tube. The bending-help device can be controlled to work simultaneously or independentlyAutomatic Lase bending angle measurement systemAngle measurementSpring-back measurementVery high accuracyWorks contactless

Company & Factory IntroductionOur Service

Pre-sales services:

1. inquiry and consulting support 2. sample testing support 3. visit our factoryAfter-sales services:

1. 2 years warranty period 2. training how to install and use the brake press machine 3. engineers available to service machinery overseasContact WaysMrs.PennyCustomer Manager

FAQ

1.Can you supply the relevant documentation?Yes, we can provide most documentation including Certificates of Analysis/Conformance; Insurance; Origin, and other export documents where required.2.What is the average lead time?For samples, the lead time is about 7 days.For mass production, the lead time is 20-30 days after receiving the deposit payment.The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try toaccommodate your needs. In most cases we are able to do so.3.What kinds of payment methods do you accept?You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.Or irrevocable LC at sight.4.What is the product warranty?We warranty our materials and workmanship.Our commitment is to your satisfaction with our products. In warranty or not, it is theculture of our company to address and resolve all customer issues to everyone's satisfaction.5.Do you guarantee safe and secure delivery of products?Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.6.How about the shipping fees?The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way.By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details ofamount, weight and way. Please contact us for further information.

Send to us