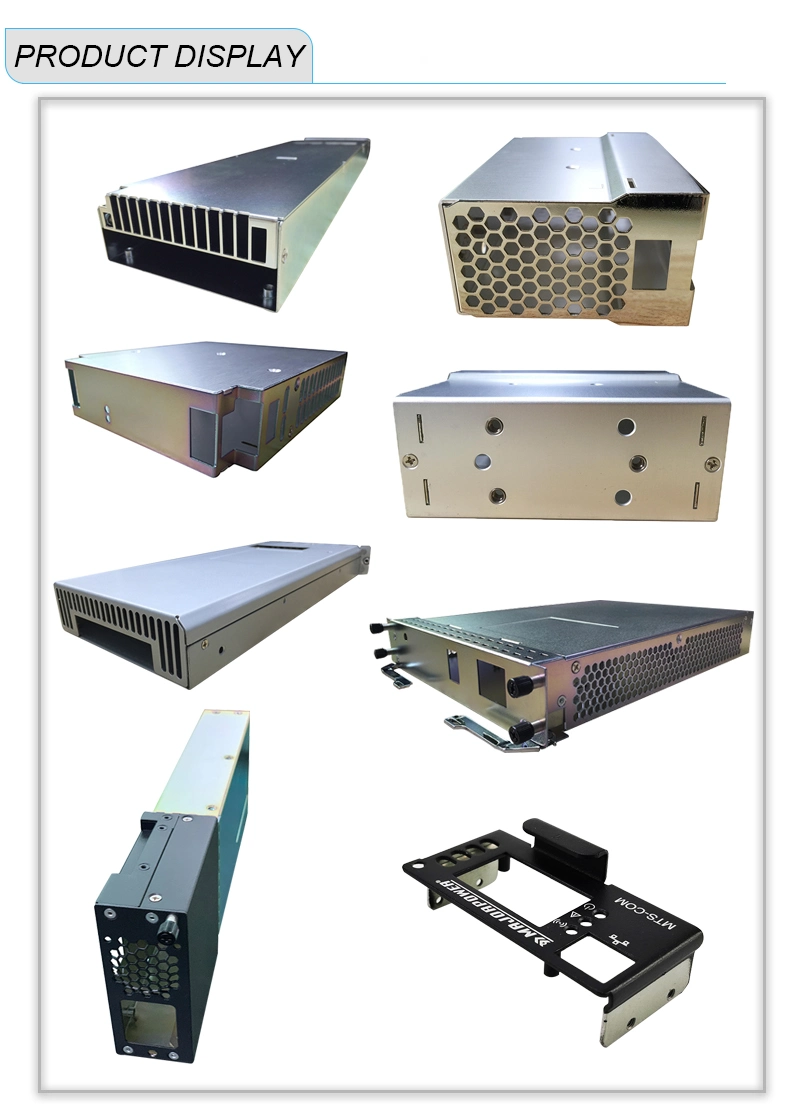

OEM Custom Aluminum Stainless Steel Sheet Metal Fabrication Stamping Laser Cutting Bending Welding Punching Car Motor Auto Spare Part CNC Precision Machining

Product Description About Us Shenzhen Runze Hardware Technology Co., Ltd., a professional Manufacturing and Trading Comb

Basic Info.

| Model NO. | RZ-1207 |

| CNC Machining or Not | CNC Machining |

| Type Available | Milling , Turning , Lathe etc |

| Title | Car Motor Auto Spare Part CNC Precision Machining |

| Service | Custom Auto Motorcycle Hardware Machinery Casting |

| Transport Package | Carton Box or as Your Request |

| Specification | custom CNC Machining |

| Trademark | RZ or customized |

| Origin | Shenzhen |

| HS Code | 7326909000 |

| Production Capacity | 20000PCS/Month |

Product Description

Product Description| Product Name | OEM Custom Aluminum Stainless Steel Stamping Laser Cutting Bending Welding Punching Car Motor Auto Spare part motorcycle hardware machinery casting CNC Precision Machining |

| Process | Punching, Stamping,bending,laser cutting |

| Type | OEM/ ODM |

| Material | Stainless Steel/ Aluminum. etc |

| Certificate | ISO9001:2015 |

| Color | Customized |

| Surface finish | As your request |

| Usage | Widely |

| Packing | By carton or as your request |

| Delivery Lead Time | 2 to 3 weeks after receive deposit |

| Size | Customized |

| Drawings format | CAD, PROE, SOLID Works and PDF |

| Surface treatment | As your request |

About Us

Shenzhen Runze Hardware Technology Co., Ltd., a professional Manufacturing and Trading Combo was established in 2003 and is located in Shenzhen City Guangdong Province, enjoying convenient transportation and beautiful environment. With 17 year history of development, we have gradually shifted from the domestic market to the development strategy of the international and domestic markets.

Runze is an OEM manufacturer focusing on metal fabrication providing with kinds of custom Sheet Metal Parts, Stamping Parts, Laser Cutting Services, High Precision CNC Machining Parts, Sheet Metal Fabricating Service and Assembly Services based on customers' drawings and designs. A variety of metal products can be made according to customers' requirements. Our company covers an area of more than 8000 square meters and over 120 employees. With Japan's advanced CNC sheet metal processing equipment, professional silk screen equipment and independent painting workshops and other professional equipment and facilities. Runze has been implementing ERP system in 2013 in order to make customer fully satisfied.

We have built up the highly efficient management system, and we also have the excellent working group members. Along with the ISO9001-2015 standards in operating, our quality assurance consciousness is melted into the minds of every staff. Our product quality has been recognized by customers, which has formed a good reputation in the many industries, such as communications industry, medical industry, utility industry, photovoltaic industry, militar industry, machinery industry and so on. For domestic market, our customers like Huawei Technologies, Mindray Medical, China Mobile and so on. For overseas market, our products have sold to Canada, United States, Germany, Australia, Japan covering 20 countries. Most of our client benefit from our OEM service.

Any of your ideas, designs, prototypes or samples, we will make it. We sincerely welcome friends from all over the world to visit our company and cooperate with us on the basis of long-term mutual benefits. Welcome to offer a trial order with your drawings! You can send us the drawing in PDF, CAD, STEP etc. file.

If all the information does not meet your cooperation needs, we sincerely can make a field inspection of our factory. Our factory is located in the Shenzhen area of the Pearl River Delta with convenient transportation. 30 minutes to Fuyong Port and 30 minutes to Airport.

Major Equipment:

-1 set of TruLaser 3030classic laser machine,

-2 sets of Japan and Germany imported CNC punch press,

-4 sets of Japanese and German imported CNC bending machine,

-8 sets punching machine ( From 40T-160T )-8 sets Squeeze riveting machine

-4 sets tapping machine-4 sets Drilling machine

-1 sets of CNC Shears-10 sets of welder

-1 powder and fluorocarbon coating lines, length of 940 meters and 120 meters.

FAQ

1. Q: Are you trading company or manufacturer?

A: We are factory,so we can provide competitive price for you.

2. Q: Do you offer OEM&ODM service?

A: Yes,of course.Most of our products are custom made.

3. Q:Does your company have tax registration certificate, organization code certificate and business license?

A: Our company has all kinds of formalities.

4. Q: How long is your delivery time?

A: Because we provide OEM service,it depends on the quantity and difficulty of the products, our usual lead time is 21-30 days.

5. Q: What is your terms of payment?

A: Payment<=1000USD,100% in advance. Payment>=1000USD, 40% T/T in advance ,balance before shipment.

6. Q:Why there is tooling cost?

A:It's mold cost.Indispensable production process.Only need to pay for first order,and we will bear maintenance cost of mold damage.

7. Q: What's your after-sale service?

A: If there is quality problem,please provide photos or test report,we will replace defective goods or return funds.

Send to us