Needling and Shaping Various Fibers Middle

Non woven needle punching machine for making carpet blanket felt fabric waste cotton recycling machine Main technical in

Basic Info.

| Needle Plate Qty | Another One as Spare Parts for Free |

| Needle Hole Diameter | 1.83mm |

| Machine Type | Be Used for Non Woven Machine Line |

| Suitable Fiber | Chemical Fiber etc |

| Machine Speed | Middle Speed |

| Product Specifications | 80 ~ 1000 G / M2 |

| Trip of Needle | 60 mm /40mm/40mm |

| Print Color | Following Customer′s Requirements |

| Customizable Width | 2000-6200mm |

| Working Width | 3600mm |

| Transport Package | Standard Export Packing for Foreign Trade |

| Specification | 2000-6200mm |

| Trademark | NHN |

| Origin | China |

| HS Code | 8449001090 |

Product Description

Non woven needle punching machine for making carpet blanket felt fabric waste cotton recycling machineMain technical indicators of Production line

To fulfill the requirements of sample and pass the test

1.Working width: 3600 mm

2.Products: all kinds of needle punching products, non-woven fabrics

3.Suitable fiber: chemical fiber, such as PET, PP specification: 1.5 ~ 6 d length of 31 ~ 51 mm polyester staple fiber and ES low melting point fiber, glass fiber, aramid fiber, etc.

4.Product specifications: 80 ~ 1000 g / m2 (1 layer)

5.Production capacity: carding machine output by 220 kg/h (6 d common assessment of chemical fiber as raw materials)

6.Total installed power: about 170 kw (actual use about 120 kw under normal)

| NO. | ITEM | DESCRIPTION |

| 1 | Model | GMZ-360M ↓/↑ |

| 2 | Dimension of M/C | L4570W1600H2425(mm) |

| 3 | Weight | 9050kgs/9350kgs |

| 4 | Total power | 22kw |

| 5 | Main motor | 15KW; 3 phase AC power 50Hz/ |

| 6 | Needle density | Depend on the customer's requirements |

| 7 | The average output | 360kg/hour(Working at width 2500mm&300g/m2 under running normal) |

| 8 | Protection | Main motor overload protection |

| 9 | The control mode | Constant power & Inverter control |

| 10 | Working width | 3600mm |

| 11 | Needle plate | High-strength aluminum alloy |

| 12 | Bearing | KOYO/Or according to the customer's requirements |

| 13 | Type of holes | Diameter1.83mm/An inverted cone |

| 18 | Trip of needle | 60 mm /40mm/40mm |

| 19 | Transfer roller | Diameter:168mm/ Chromium plating process/high quality 50# steel |

| 20 | Needle plate | High strength alloys and shock shape /totally 18 mm thickness |

| 21 | The main shaft & other work shaft | Diameter: 80mm/ Dynamic balance and strength strengthening heat treatment/high quality steel |

| 22 | Print Color | Following customer's requirements |

| 23 | The control cabinet and panel | Digital display instrument, and equipped with knob regulator, professional electric schematic diagram |

| 24 | Note | Direction:↓first then ↑/The round-trip distance of the needle can be adaptive adjustment according to the thickness of the raw materials. |

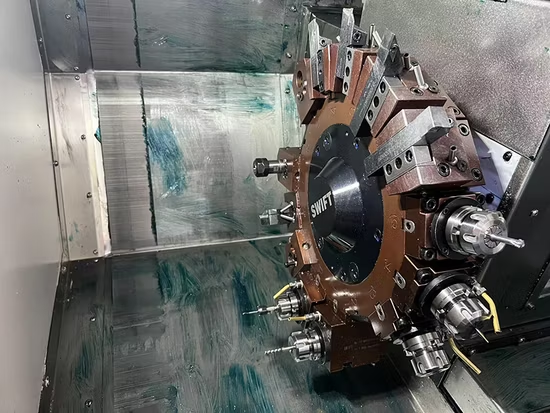

- Adopt CNC gantry milling machine with good stability, high precision and high finish

- Automatic oil injection system,good for machine lubrication and maintenance

- Cagnesium alloy/PU combined needle board locked firmly by lock-bolt or air tube; multi random computer needling methods for needle board

- Chrome plated delivery rollers with carved or patterned surface

Send to us