CNC Gantry Machining Center Moving Column Dynamic Beam Drilling Milling Machine Center for Sheet Metal Processing

Overview Package Size 2400.00cm * 2700.00cm * 3600.00cm Package Gross Weight 5000.000kg Product Description The machine

Overview

Applied to new energy vehicle battery trays, rail transit, mechanical manufacturing, and sheet metal processing

PHA series

PHA-CNC3000

PHA-CNC6000

(Other lengths can also be customized)

Y-axis travel 2000mm

Z-axis travel 800mm

The entire series adopts BT40 spindle tapered holes, with a spindle outer diameter of 140mm

Equipped with a disc type 24 tool magazine capacity

Equipped with automatic chip removal system

Equipped with automatic cooling system

Product Parameters

Applications

Basic Info.

| Model NO. | PHA CNC6000 |

| Object | New Energy Vehicle Battery Trays |

| Structure | Bed type |

| Milling Cutter Type | Vertical Milling Cutter |

| Milling Cutter Structure | Indexable Type |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Certification | GS, CE, ISO 9001 |

| Condition | New |

| Y Route or Distance of Travel | 2000mm |

| Operating System | Fanuc Siemens |

| Z Route or Distance of Travel | 800 mm |

| X Route or Distance of Travel | 3000-6000 (Other Length) |

| Taper Hole of Spindle | Bt40 Od: 120mm |

| Transport Package | Plywood Case |

| Trademark | Ubright |

| Origin | Cn |

| HS Code | 8457101000 |

Packaging & Delivery

Package Size 2400.00cm * 2700.00cm * 3600.00cm Package Gross Weight 5000.000kgProduct Description

Product Description

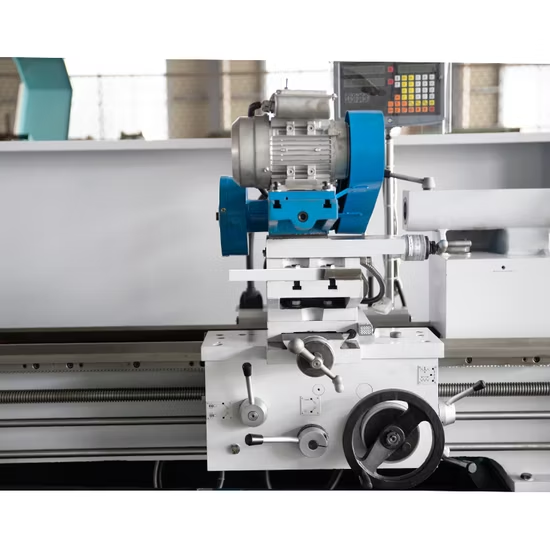

The machine for column mobile processing center, the whole machine adopts moving column, ensure the overall rigidity and compact structure, machine rigidity is good. Easy to dispose of scraps and drainage. Good precision retention, can be used for precision cutting;automotive, textile, window frame, civil aviation, motor, valve and other industries.Applied to new energy vehicle battery trays, rail transit, mechanical manufacturing, and sheet metal processing

PHA series

PHA-CNC3000

PHA-CNC6000

(Other lengths can also be customized)

Y-axis travel 2000mm

Z-axis travel 800mm

The entire series adopts BT40 spindle tapered holes, with a spindle outer diameter of 140mm

Equipped with a disc type 24 tool magazine capacity

Equipped with automatic chip removal system

Equipped with automatic cooling system

Product Parameters

| route or distance of travel | X route or distance of travel | 3000-6000 (other length) |

| Y route or distance of travel | 2000mm | |

| Z route or distance of travel | 800mm | |

| principal axis | main shaft speed | 10000rpm (20000rpm electric spindle) |

| taper hole of spindle | BT40 OD: 120mm | |

| tool magazine | Knife library form | disc type |

| Knife library capacity | 24 pcs | |

| Adjacent change knife time | 2 sec | |

| translational speed | X/Y axis shift | 40/50 m/min |

| Z axis shift | 20 m/min | |

| Cut into give speed | 15000 mm/min | |

| operating system | FANUC | SIEMENS |

| Spindle drive motor | 7.5 kw | 11 kw |

| X drive motor | 3.0+3.0 KW | 3.1+3.1 KW |

| Y / Z drive motor | 3.0/3.0 KW | 3.1/3.1KW |

| lube oil system | self-lubricate | |

| coolant passage | injection water cooling | |

| definition | X axis positioning is accurate | 0.05 mm (Rating 0.01mm) |

| The Y / Z is positioned precisely | 0.03/0.02 mm | |

| Repeat repeat precision (X / Y / Z) | 0.01mm | |

| rating of machine | Pressure demand | 6 kg/cm² |

| altitude | 3900 mm | |

| floor space | 6200-20000*4400 mm | |

| weight | 17000-40000kg | |

Send to us